When you decide to source wood goods from China, you must know what type of wood species your products need to be made from the first time. This basic expertise will enable you to identify the best and worst suppliers during the sourcing process, as well as keep your sourcing costs under control

- Construction Of the Wood

- Extrinsic Factors Determining the Quality of the Wood

- Intrinsic Factors that Determine the Quality of Wood

- Common Types Of Wood

Construction of the wood

Wood is made up of many cells, which vary in shape, size, and arrangement, making it an anisotropic material with a highly complex structure. By sawing the wood in different directions, numerous facets can be obtained, the three typical ones being: cross-section, chord-section, and diameter-section.

Transverse section: the section obtained by sawing perpendicular to the direction of growth of the tree. The cellular tissue in wood runs parallel to the grain. This cut is hard, resistant to wear and tear, easily broken, and difficult to plane.

The annual rings and wood rays can be clearly observed in the cross-section and are important for identifying the wood.

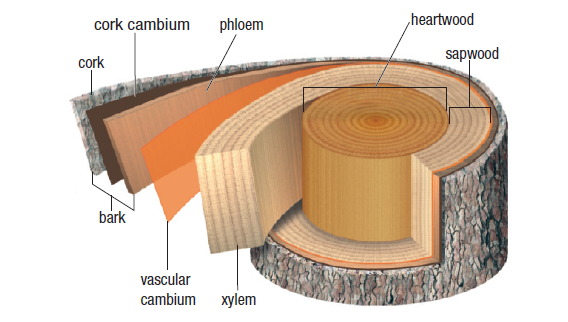

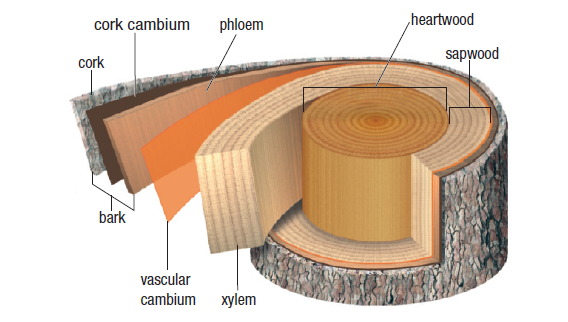

- The bark is the tree’s protective layer, and transports nutrients during growth.

- Forming layer The growing tissue of the tree is located between the inner layer of the bark and the xylem.

- Xylem The part of the tree between the pith and the forming layer is the xylem; it includes the sapwood and heartwood, which are solid in structure and are the main parts used as building materials, etc. The sapwood is the lighter-colored part near the bark; the heartwood is the darker-colored part near the pith.

- Pith: Tubular in shape, running longitudinally through the whole trunk and the center of the branches, it is made up of the earliest thin cells of the tree, which are soft and easily decayed.

- Pith line: a vertical fiber distributed in a radial pattern across the annual rings from the pith, called the pith line. It can be seen in both cross-sections and longitudinal sections of the trunk. In some species, the medullary line is thick and obvious, such as Quercus, elm, and willow. In some species, the pith line is small and inconspicuous, such as in coniferous woods, rowan, and birch.

- The annual rings: concentric circles of woody layers are formed in the cross-section, and this thin layer corresponds to one year of tree growth, called the annual rings. Because of the seasonal changes in the growth process of trees, spring growth is vigorous, the cells are large and loosely arranged, the cell walls are thin, and the color is light, which is called spring wood (early wood). In summer, when growth is slow, cells are small, cell walls are thick, tissue is tight and solid, and the color is darker, known as summer timber (late timber). The tree grows for one year and a thin layer is added to the cross-section, hence the name annual rings.

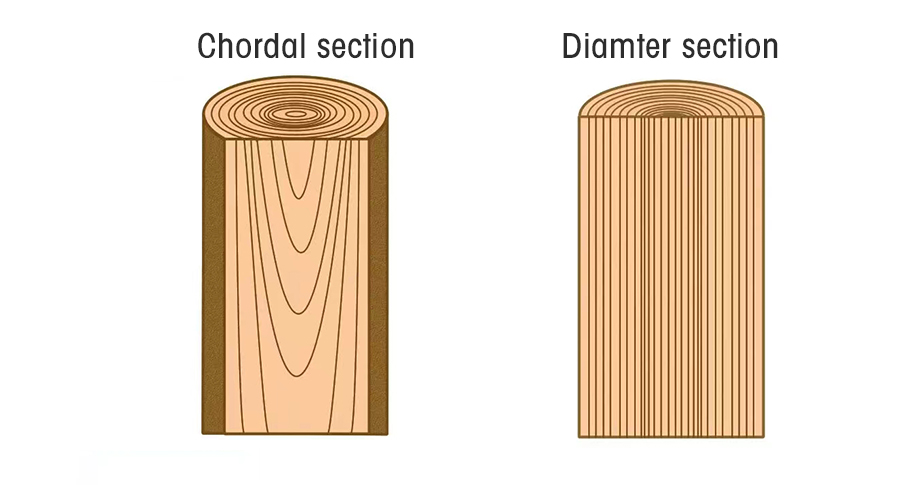

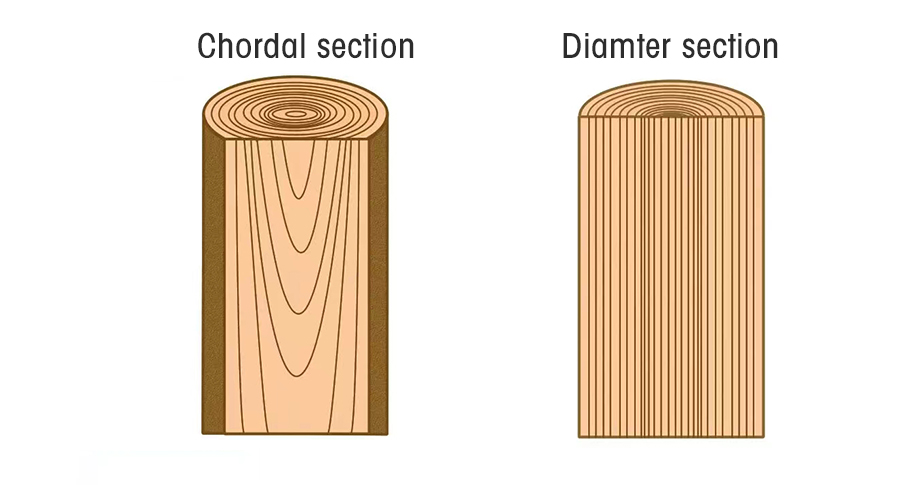

Diameter section: a longitudinal section perpendicular to the annual rings, cut from the bark through the pith, the section is a standard diameter cut. The diameter cut has less shrinkage, less warping, straighter grain, and better hardness.

Chordal section: the longitudinal sawn section in the direction of the trunk is called the chord section. The standard chord cut is parallel to the annual rings, so it should be curved rather than flat. In woodworking, the spin-cut sheet tends to approximate the standard chordal plane. The V-shaped pattern of the annual rings on a chord-cut panel is more attractive but is prone to warping and deformation. Both the diameter and chord cuts are sawn along the trunk of the tree, so they are also known as longitudinal cuts.

Extrinsic factors

1、Ttemperature

temperature is the main factor affecting the drying speed of wood. The temperature rises, the water pressure in the wood rises, and the viscosity of liquid-free water decreases, which is conducive to promoting the flow and diffusion of water in the wood; the soluble moisture capacity of the drying medium of copper wire increases, which speeds up the evaporation of water on the surface of the wood. If the external temperature is too high, it will cause cracking and deformation of the wood, which will produce reduced mechanical strength, discoloration, and other problems

2. Humidity:

The relative humidity is an important factor affecting the drying speed of wood. In the case of the same temperature and airflow speed, the higher the relative humidity, the greater the partial pressure of water vapor in the medium, the more difficult it is for the moisture on the surface of the wood to evaporate into the medium, the slower the drying speed; when the relative humidity is low, the surface moisture evaporates quickly, the moisture content of the surface layer decreases, the moisture content gradient increases, the moisture diffusion increases, and the drying speed is fast. But the relative humidity is too low, will cause cracking and honeycomb and other drying defects problems occur or even aggravate.

3. Airflow circulation speed

Airflow circulation speed is another factor that affects the drying speed of wood. High-speed airflow can destroy the saturated steam boundary layer on the surface of the wood, thus improving the heat and mass transfer conditions between the medium and the wood and speeding up the drying speed. For difficult-to-dry timber or when the moisture content of the timber is low, the internal movement of moisture within the timber determines the drying speed; there is no practical significance in speeding up the evaporation of surface moisture by increasing the large media flow rate, but on the contrary, it increases the moisture content gradient and increases the risk of producing drying defects. Therefore, hard-to-dry timber does not require a large media circulation rate.

The above three factors are external factors that can be artificially controlled, properly controlled, and can speed up the drying speed under the premise of ensuring the drying quality of wood. For example, when drying thin boards of coniferous wood or soft broad-leaved wood, as the internal moisture movement of the wood is easier, the dry ball temperature can be raised, the medium humidity lowered and the airflow circulation speed increased to speed up the drying speed; but when drying mahogany wood or thick boards, a lower temperature, higher humidity, and a smaller airflow circulation speed are appropriate to avoid drying defects.

Intrinsic factors

1. Wood species and structural characteristics Different species of wood have different structures, the size and number of their grain pores, as well as the size of the micro-pores on the grain pore membrane are very different, so the ease of movement of water along the above path is different, wood species is the main internal factors affecting the drying speed. The drying speed of hard broadleaf wood with ring holes (e.g. sourwood) is significantly less than that of broadleaf wood with loose holes because of the large number of fillings in the ducts and pores and the small diameter of the micropores in the grain pore membrane; in the same species, the density increases, the resistance to the flow of water in the large capillaries increases and the path of water diffusion in the cell walls is prolonged, making it very difficult to dry.

2. Wood thickness The conventional drying process of wood can be approximated as a one-dimensional heat and mass transfer process along the direction of wood thickness, the thickness increases, the heat and mass transfer distance becomes longer, the resistance increases, and the drying speed decreases significantly.

3. Wood moisture content below the fiber saturation point, as the moisture content decreases, the lateral diffusion coefficient of absorbing water decreases, while the diffusion coefficient of water vapor in the cell cavity increases, due to the drying process of water vapor diffusion in the cell cavity accounted for a small proportion, the lower the water content the longer the water diffusion path, so the lower the moisture content the more difficult to dry.

4. Wood heart and sapwood broadleaf heartwood cells in the inclusions are more, conifer heartwood in most of the grain pores are closed, so the heartwood is more difficult to dry than the sapwood.

5. Wood grain wood rays are conducive to moisture conduction, along the radial direction of the wood moisture conduction than along the chord about 15%-20% larger, so the chord cut board is usually drier faster than the diameter cut board.

Although the internal factors cannot be controlled, as long as the characteristics of the wood are taken into account and the drying equipment and techniques are used wisely, the drying speed can also be improved, both to reduce unnecessary losses and to improve the drying effect while maintaining the timber properties.

Common types of wood

The reason why we like logs is that their unique and soft texture gives a natural and intimate feel to life, and the types commonly used in our daily lives are as follows:

Name: Pinewood

Odor: pine-scented

Color: light yellow

Texture: maintain the natural color of pine, the texture is clear and beautiful

Features: Pine is a soft wood, with beautiful lines and a classy atmosphere, but it reacts quickly to atmospheric temperatures and is easily swollen, difficult to dry naturally, and prone to cracking and deformation.

Name: Beechwood

Colour: yellowish in color

Texture: Layers of texture, good visual effect

Features: Highly malleable, easy to bend under steam, can be made into a wide variety of shapes, is resistant to wear and tear, has a hard texture, delicate pores, and is easy to work with. This makes it particularly suitable for furniture and small craft items such as wooden plates, chopping boards, and decorative woodwork.

Name: OAK

Color: oak with a yellow-brown to reddish-brown heart

Texture: has a relatively distinctive mountain line wood grain

Features: tougher, straighter grain, coarse structure, high mechanical strength, resistant to wear and tear, but the wood is dense, not easy to dry, and more prone to cracking when used in furniture.

Name: Cherrywood

Color: Lustrous brown or redwood

Texture: Cherry wood naturally contains brown heart spots and small gum nests, with a fine, clear grain

Features: It’s has good bending properties, medium bending and impact strength, low hardness, can be dried quickly and has good stability after drying. It is suitable for high-end furniture or carving, such as high-end carved jewelry boxes.

Name: White Currant

Color: The sapwood is almost white, and the heartwood varies in color from light brown to light red to brown

Texture: Ash willow is characterized by a pattern on the chordal surface of the timber that resembles the large ripples that form when a stone is thrown into the water.

Features: smooth cut, low color difference, good toughness, and resistance to processing. The hardwood type is suitable for manufacturing items that require toughness, bending, or resistance to vibration.

Name: Walnut

Color: Walnut has creamy white sapwood and a light to dark brown chocolate heartwood, with occasional purple and darker streaks

Texture: The grain of walnut is generally straight, sometimes with wavy or curly grain.

Features: The wood is potent, stable, and malleable, and its products have excellent performance and long life. Suitable for medium to high-end crafts: e.g. storage boxes, tissue boxes, etc.

Name: Elmwood

Texture: straight and rough, clear and straightforward.

Features: light and stiff, high mechanical strength, can be used for furniture decoration, etc., not easily deformed and insects. It is resistant to corrosion and is suitable for fine, high-grade crafts.

Color: the heart and sapwood of elm are clearly differentiated, with the sapwood being a dark yellow and the heartwood a dark purplish grey.

Name: Brich

Color: The wood is light brown to reddish brown with a shiny surface and smooth texture, yellowish white with a slightly brownish tinge.

Texture: It has many patterns at the roots and nodes with a clear pattern

Features: pure and delicate, slightly heavy and complex, fine structure, high mechanical strength, processed, smooth cut, good painting and gluing properties, high durability and not quickly decayed.